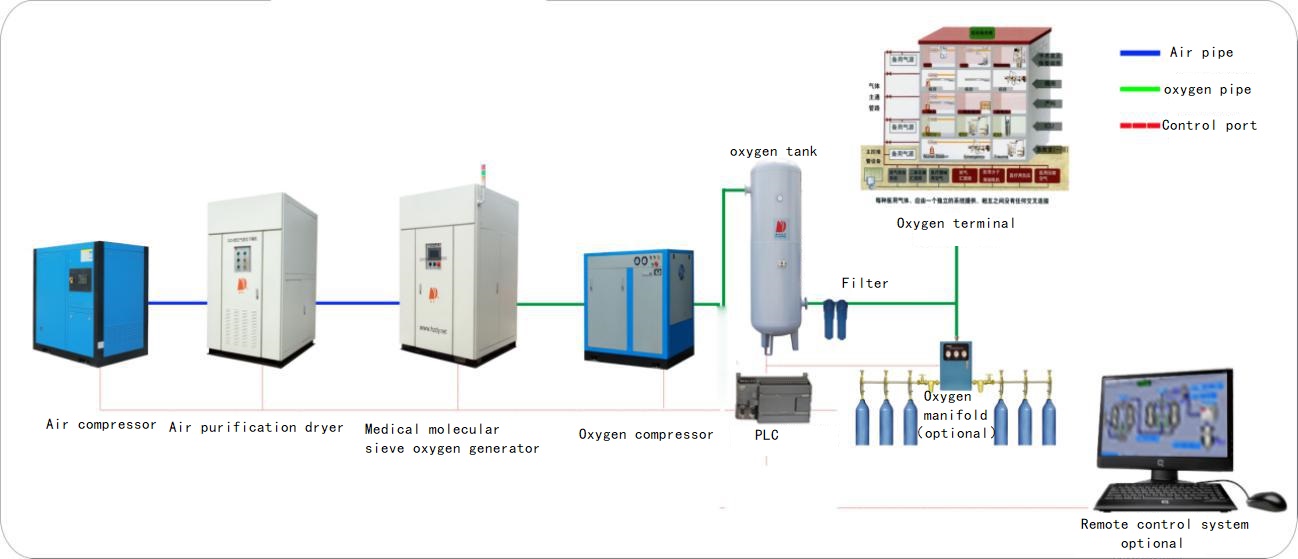

Medical gas equipments type psa oxygen generator

Technical indicators

Oxygen production: 5-200N m3/h

Oxygen purity: 90 % -93 %

Oxygen pressure: 0.3 Mpa

Dew point: -40 °C(under normal pressure)

Technical characteristics

1. Compressed air is equipped with air purification and drying treatment device, clean and dry air, which is conducive to the long-term service life of molecular sieves.

2. The new pneumatic cut-off valve adopted has a fast opening and closing speed, no leakage, long switching life, and can satisfy the variable pressure adsorption process frequently and has high reliability.

3. Perfect process design, selection of new molecular sieves

4. Adopt new oxygen production festival, continuously optimize the device design, reduce energy consumption and capital investment

5. Compact equipment structure design, reduce land area

6. The equipment performance is stable, using PLC control, can achieve full automatic operation, the annual operation failure rate is low

Process flow brief description