shelter hospital oxygen plant

Uses of Oxygen

Oxygen is a tasteless gas. It has no smell or color. It comprises 22% of the air. The gas is part of the air people use to breathe. This element is found in the human body, the Sun, oceans and the atmosphere. Without oxygen, humans will not be able to survive. It is also part of the stellar life cycle.

Common Uses of Oxygen

This gas is used in various industrial chemical applications. It is used to make acids, sulfuric acid, nitric acid and other compounds. Its most reactive variant is ozone O3. It is applied in assorted chemical reactions. The goal is to boost reaction rate and oxidation of unwanted compounds. Hot oxygen air is required to make steel and iron in blast furnaces. Some mining companies use it to destroy rocks.

Usage in the Industry

Industries use the gas for cutting, welding and melting metals. The gas is capable of generating temperatures of 3000 C and 2800 C. This is required for oxy-hydrogen and oxy-acetylene blow torches. A typical welding process goes like this: metal parts are brought together.

A high temperature flame is used to melt them by heating the junction. The ends are melted and solidify. To slice metal, one end is heated until it turns red. The oxygen level is augmented until the red hot component has oxidized. This softens the metal so it can be hammered apart.

Atmospheric Oxygen

This gas is required to produce energy in industrial processes, generators and ships. It is also used in airplanes and cars. As liquid oxygen, it burns spacecraft fuel. This produces the thrust needed in space. Astronauts’ spacesuits have close to pure oxygen.

Application :

1:Paper and Pulp industries for Oxy bleaching and delignification

2:Glass industries for furnace enrichment

3:Metallurgical industries for oxygen enrichment of furnaces

4:Chemical industries for oxidation reactions and for incinerators

5:Water and Wastewater treatment

6:Metal gas welding, cutting and brazing

7:Fish farming

8:Glass industry

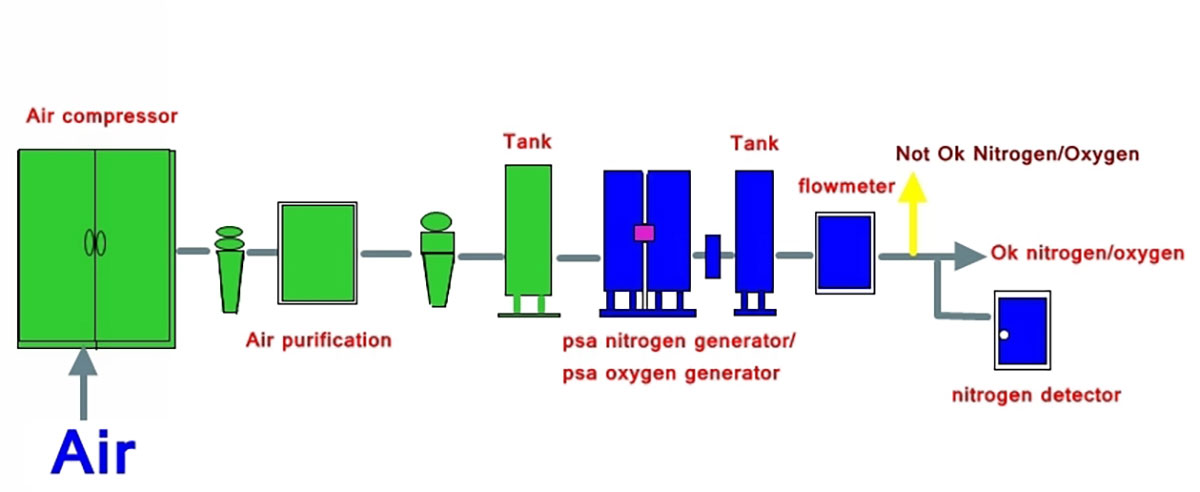

Process flow brief description

Selection table of medical molecular sieve oxygen system

Selection table of medical molecular sieve oxygen system

| Model | Flow( Nm³/h) | Air need(Nm³/min) | Inlet/Outlet size(mm) | Air Dryer model | |

| KOB-5 | 5 | 0.9 | 15 | 15 | KB-2 |

| KOB-10 | 10 | 1.6 | 25 | 15 | KB-3 |

| KOB-15 | 15 | 2.5 | 32 | 15 | KB-6 |

| KOB-20 | 20 | 3.3 | 32 | 15 | KB-6 |

| KOB-30 | 30 | 5.0 | 40 | 15 | KB-8 |

| KOB-40 | 40 | 6.8 | 40 | 25 | KB-10 |

| KOB-50 | 50 | 8.9 | 50 | 25 | KB-15 |

| KOB-60 | 60 | 10.5 | 50 | 25 | KB-15 |

| KOB-80 | 80 | 14.0 | 50 | 32 | KB-20 |

| KOB-100 | 100 | 18.5 | 65 | 32 | KB-30 |

| KOB-120 | 120 | 21.5 | 65 | 40 | KB-30 |

| KOB-150 | 150 | 26.6 | 80 | 40 | KB-40 |

| KOB-200 | 200 | 35.2 | 100 | 50 | KB-50 |

| KOB-250 | 250 | 45.0 | 100 | 50 | KB-60 |

| KOB-300 | 300 | 53.7 | 125 | 50 | KB-80 |

| KOB-400 | 400 | 71.6 | 125 | 50 | KB-100 |

| KOB-500 | 500 | 90.1 | 150 | 65 | KB-120 |

Our service

We have been making series of air separation units for nearly 20 years. With the support of a perfect management system and advanced manufacturing tools, we make constant technological improvements. We have built long-term good cooperation with many design and research institutes. Our air separation units have better and better performance.

Our company has passed ISO9001:2008 certification. We have won many honors. The strength of our company is constantly growing.

We warmly welcome all of our customers to build win-win cooperation with us.