Factory wholesale Caire Oxygen Concentrator - mobile cabin hospital oxygen plant – Sihope

Factory wholesale Caire Oxygen Concentrator - mobile cabin hospital oxygen plant – Sihope Detail:

Technical Features

Oxygen produced in our high purity oxygen generator meets the standards of US Pharmacopeia, UK Pharmacopeia &Indian Pharmacopeia. Our oxygen generator is also used in hospitals because the installation of oxygen gas generator on-site helps the hospitals to produce their own oxygen and stop their dependency on oxygen cylinders bought from the market. With our oxygen generators, the industries and medical institutions are able to get uninterrupted supply of oxygen. Our company uses cutting-edge technology in the making of the oxygen machinery.

Salient features of PSA oxygen generator plant

• Fully automated- systems are designed to work unattended.

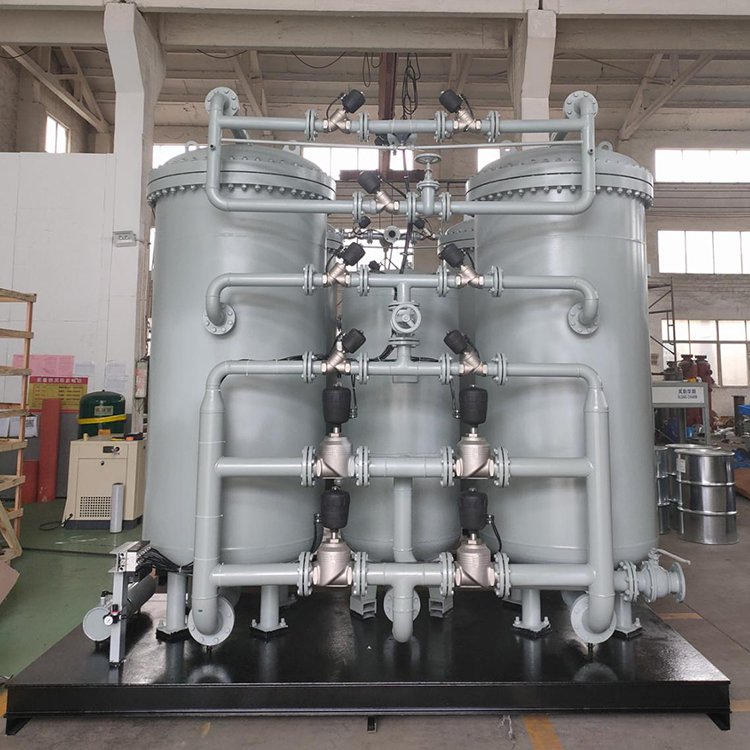

• PSA plants are compact taking little space, assembly on skids, prefabricated and supplied from factory.

• Quick start-up time taking only 5 minutes to generate oxygen with desired purity.

• Reliable for getting continuous and steady supply of oxygen.

• Durable molecular sieves that last around 10 years.

Application :

a. Ferrous metallurgy: For electric furnace steel making, blast furnace iron making, cupola oxygen blasting and heating and cutting, etc

b. Non-ferrous metal refinery: It can improve productivity and reduce energy cost, also protect our environment.

c. Water process: For oxygen aeration active mud process, reaeration of surface water, fish farming, industrial oxidation process, humid oxygenation.

d. Customized equipment with pressure high up to 100bar, 120bar, 150bar, 200bar and 250 bar are available for cylinder filling.

e. Medical-grade O2 gas can be obtained by equipping extra purifying device for removing bacteria, dust and odor.

f. Others: Chemical industry production, solid garbage burning, concrete production, glass manufacturing…etc.

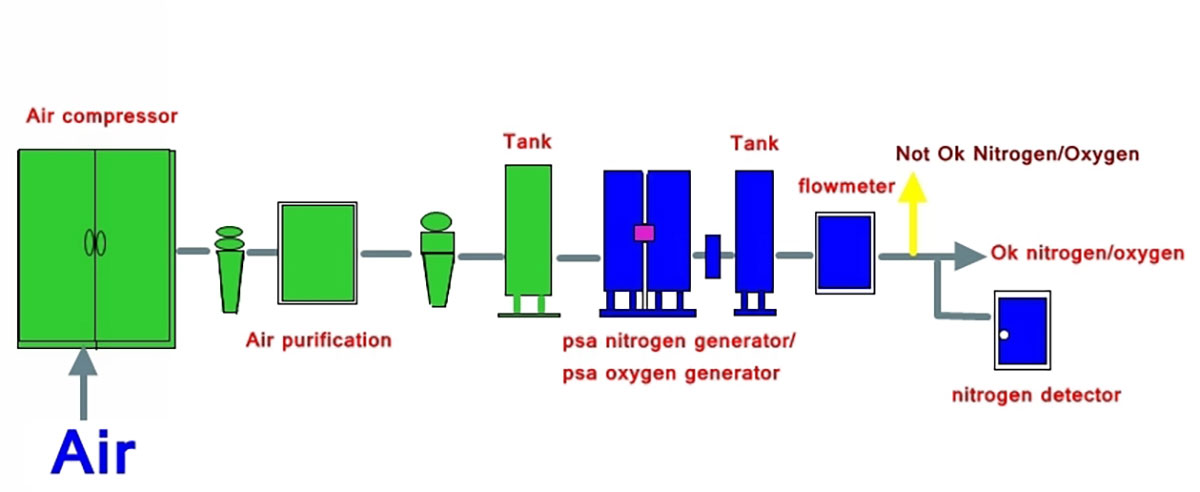

Process flow brief description

Selection table of medical molecular sieve oxygen system

| Model | oxygen content Nm³/h | Installed function KW | The quantity of hospital bed(piece) |

| SND-3Y | 3 | 5 | 100 |

| SND-5Y | 5 | 7 | 150 |

| SND-8Y | 8 | 11 | 250 |

| SND-10Y | 10 | 15 | 300 |

| SND-15Y | 15 | 22 | 450 |

| SND-20Y | 20 | 30 | 600 |

| SND-25Y | 25 | 37 | 750 |

| SND-30Y | 30 | 37 | 900 |

| SND-40Y | 40 | 45 | 1200 |

| SND-50Y | 50 | 55 | 1500 |

| SND-60Y | 60 | 75 | 1800 |

Delievery

Product detail pictures:

Related Product Guide:

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for Factory wholesale Caire Oxygen Concentrator - mobile cabin hospital oxygen plant – Sihope , The product will supply to all over the world, such as: Korea, Denmark, Greek, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The sales manager is very patient, we communicated about three days before we decided to cooperate, finally, we are very satisfied with this cooperation!